Industry 4.0

2024-2025

Automating depth measurement for mining and engineering

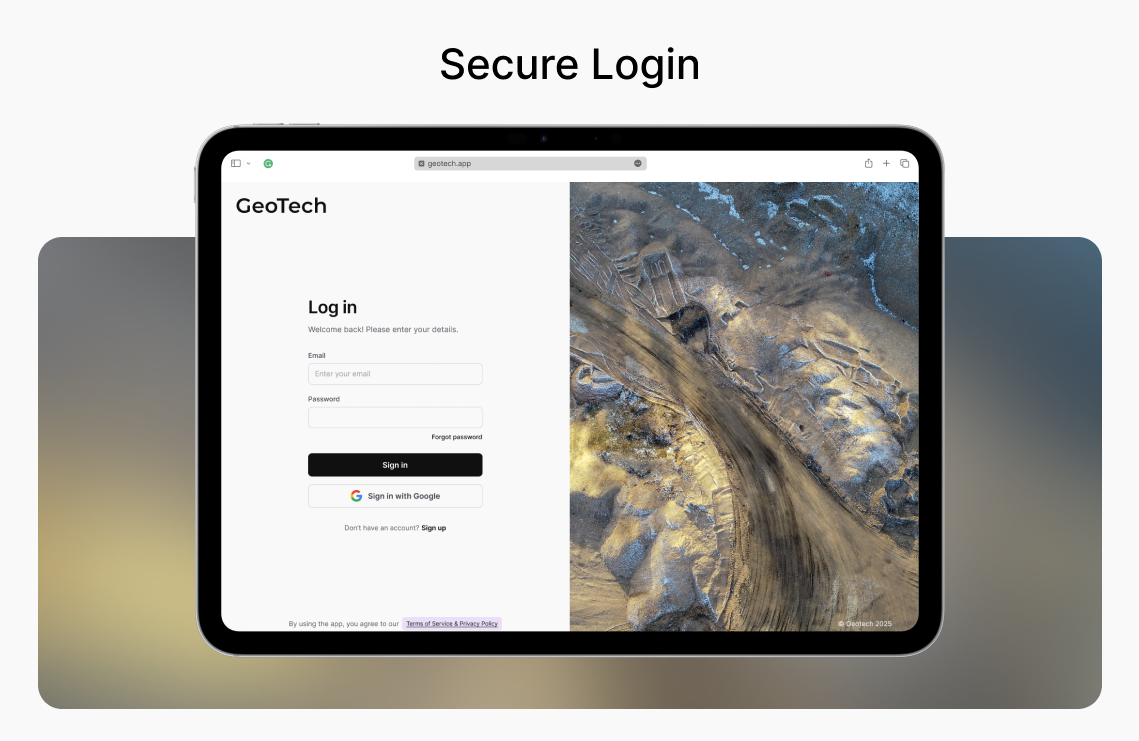

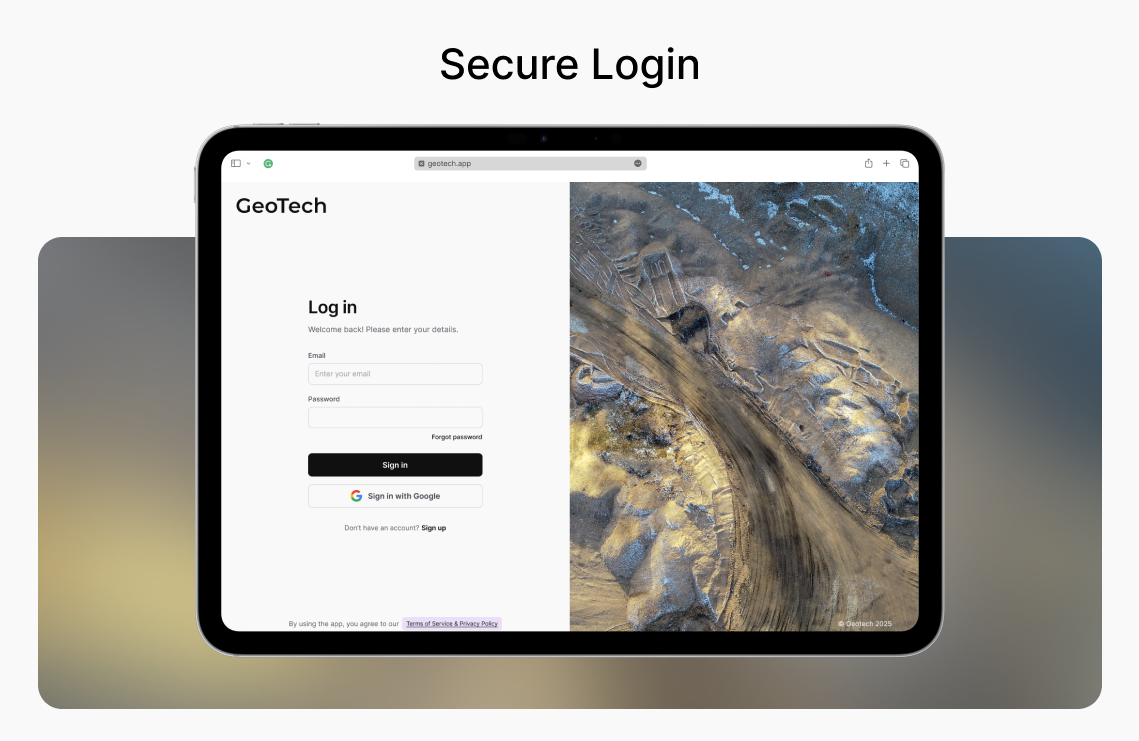

This was a challenging project due to its technical specifications. My main goals were to conduct stakeholder interviews, complete the project brief, define core functionalities in collaboration with the development team, and successfully launch the web application.

01

About the Platform

The project focuses on building an automated depth measurement platform for the mining, minerals, and civil engineering industries.

The goal is to design a product that combines advanced spatial analytics with a strategic design approach rooted in industry needs and design thinking principles.

02

Primary Market Research

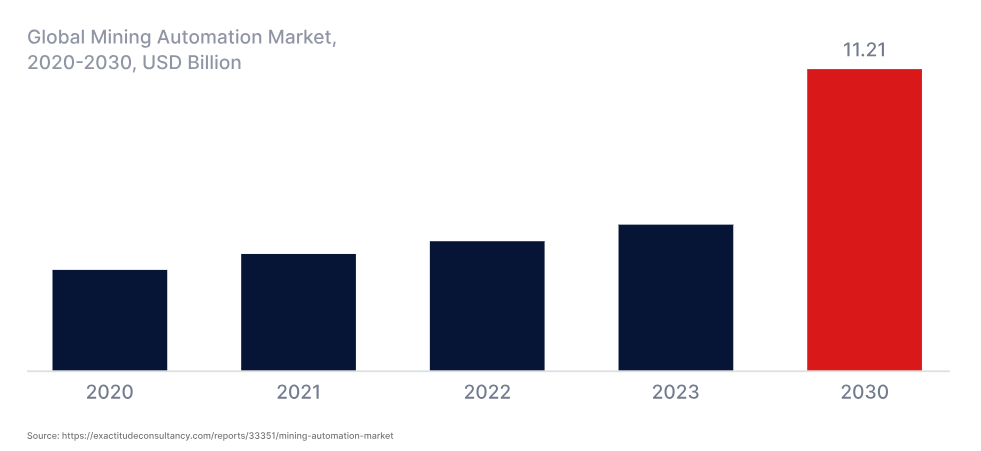

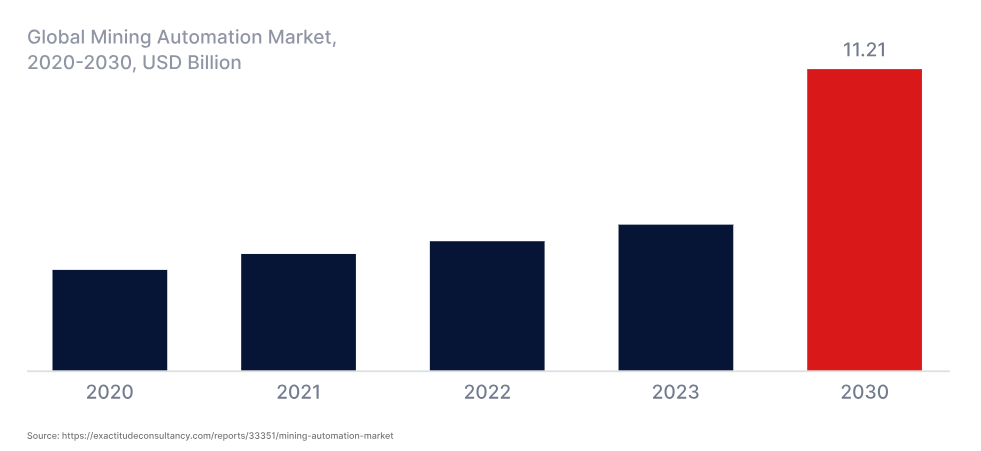

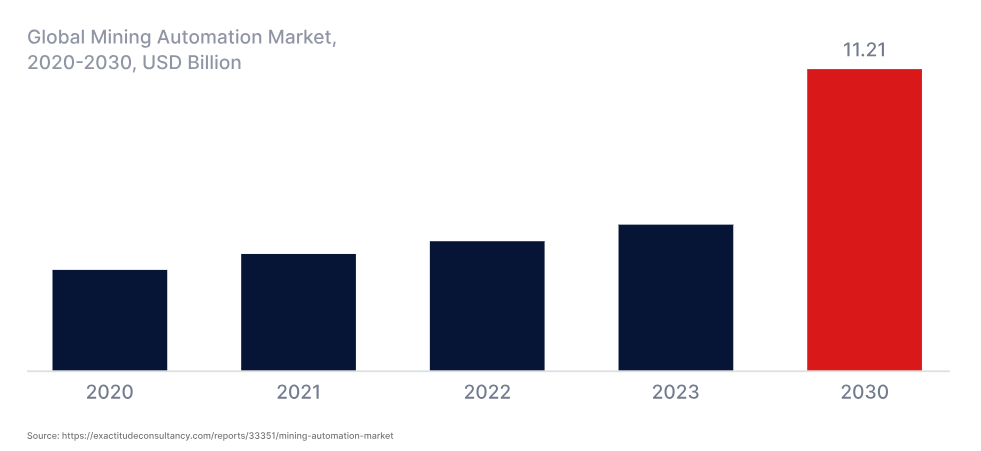

Mining Automation Market valued at USD 5.33 billion in 2023, projected to reach USD 11.21 billion by 2030, growing at a CAGR of 11.19%.

03

Primary Market Research

Market Segmentation Analysis

The global mining automation market is segmented into 5 key categories: automation type, equipment type, mining technique, application, and end-use. This segmentation helps identify specific market trends, assess growth potential in sub-segments.

Automation Type

Automation equipment such as autonomous vehicles and robotic machinery are transforming mine sites by enabling 24/7 operation, reducing downtime, and minimizing the risks associated with manual labor in hazardous environments.

Equipment Type

The mining automation market encompasses a wide range of automated machinery, including:1. Automated Excavators and Loaders;2. Robotic Trucks and Loaders;3. Automated Drilling Systems;4. Autonomous Haulage Systems;5. Automated Mine Planning and Management Systems.

Mining Technique

Based on mining techniques, the market is divided into surface mining and underground mining. The underground mining segment is currently leading the market. Automation technologies are particularly valuable in underground environments due to the inherent challenges and risks associated with confined spaces, unstable geological conditions, and limited ventilation. Remote-operated machinery and intelligent drilling systems are well-suited to overcome these hurdles while ensuring operational safety and efficiency.

By Application

Mining automation is applied across three major operational phases:1. Mine Development;2. Mine Maintenance;3. Mining Operations.

By End-Use

The end-use segmentation includes:1. Mineral Mines;2. Coal Mines;3. Metal Mines.

04

Problem Definition Statement

''Mining companies are not well-known as technological disruptors. But there is a mandate now to invest more in technology to come up with solutions to the challenges of today — from ESG to productivity to ways of lowering costs.''

Manuel Fernandes, KPMG in Brazil

05

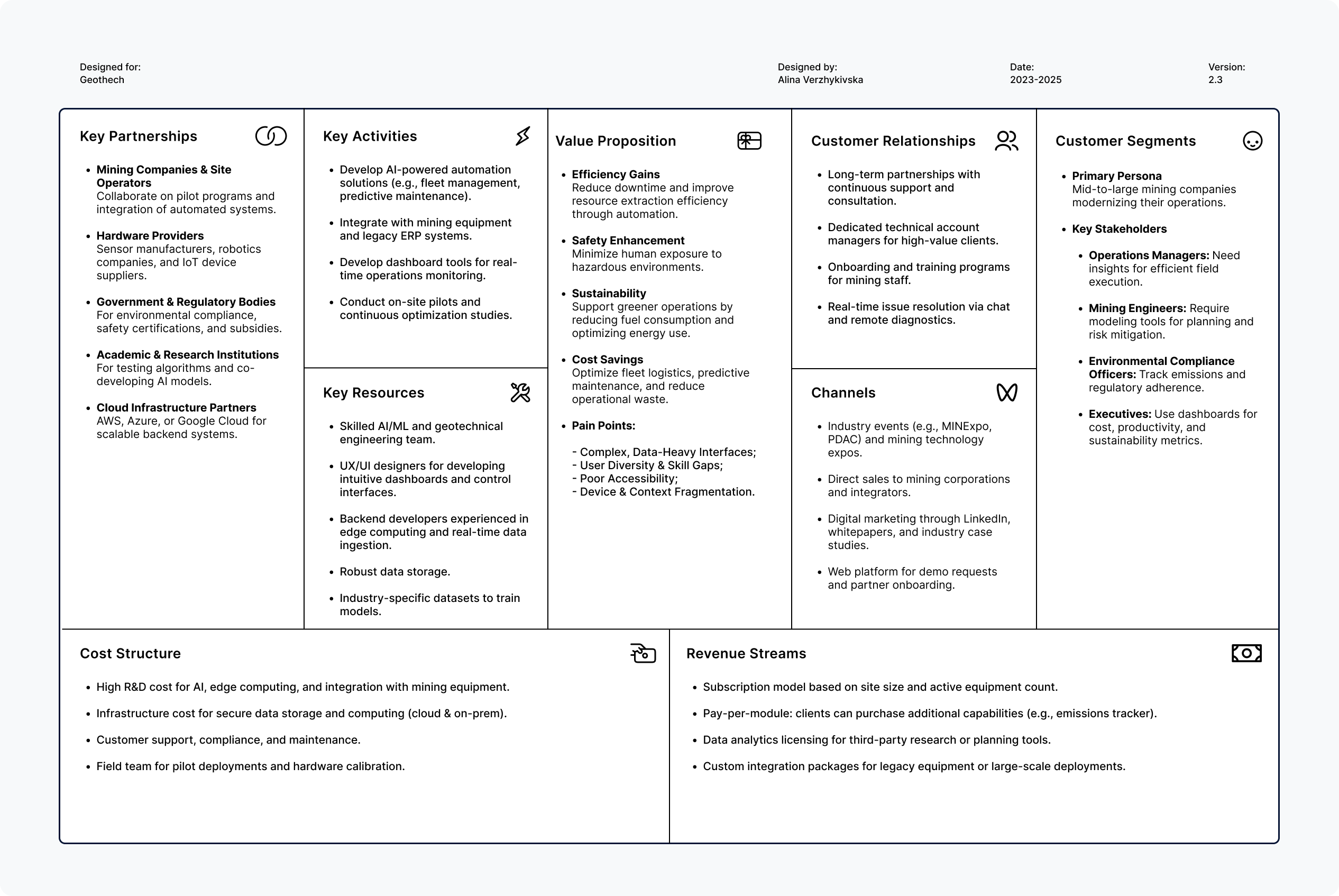

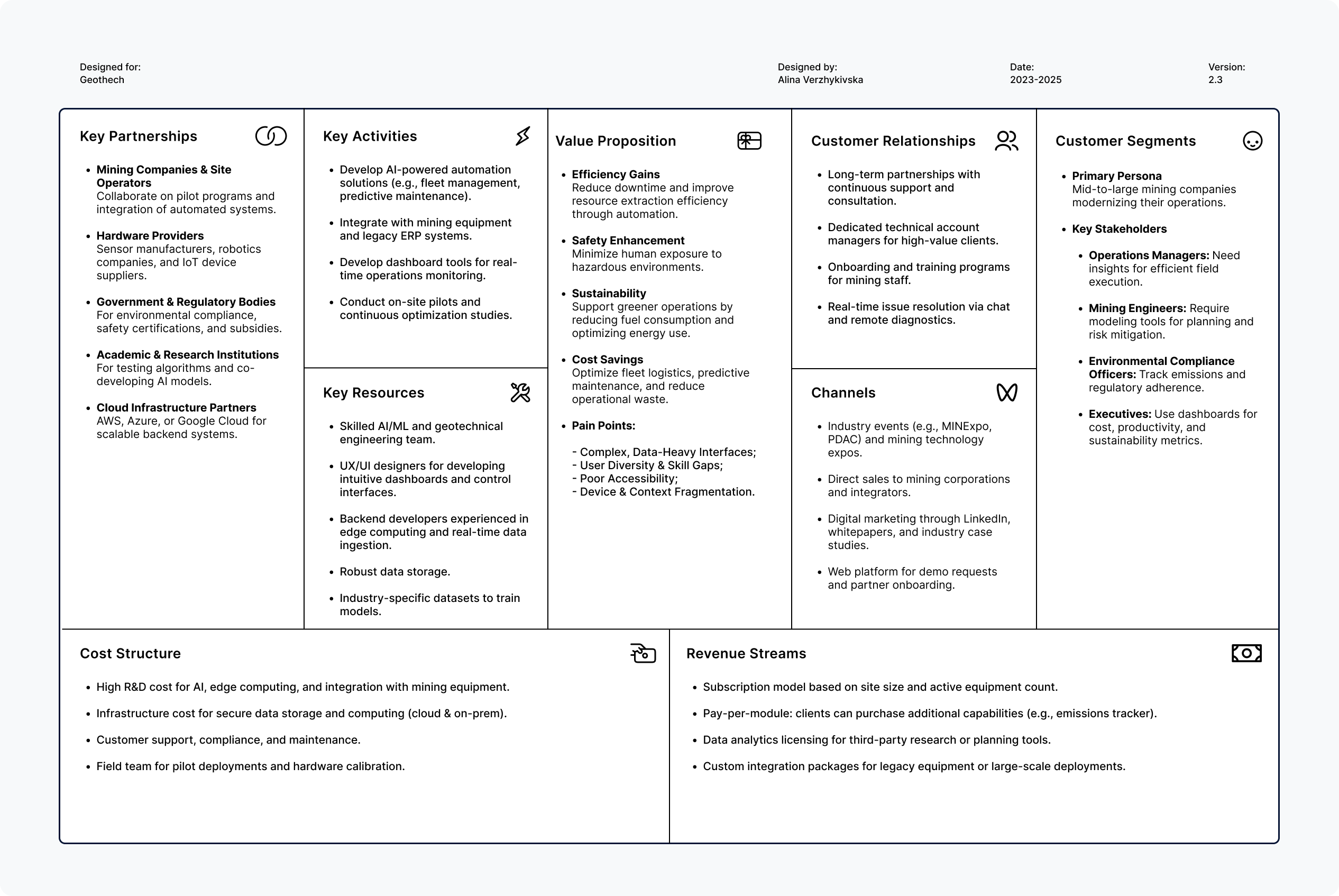

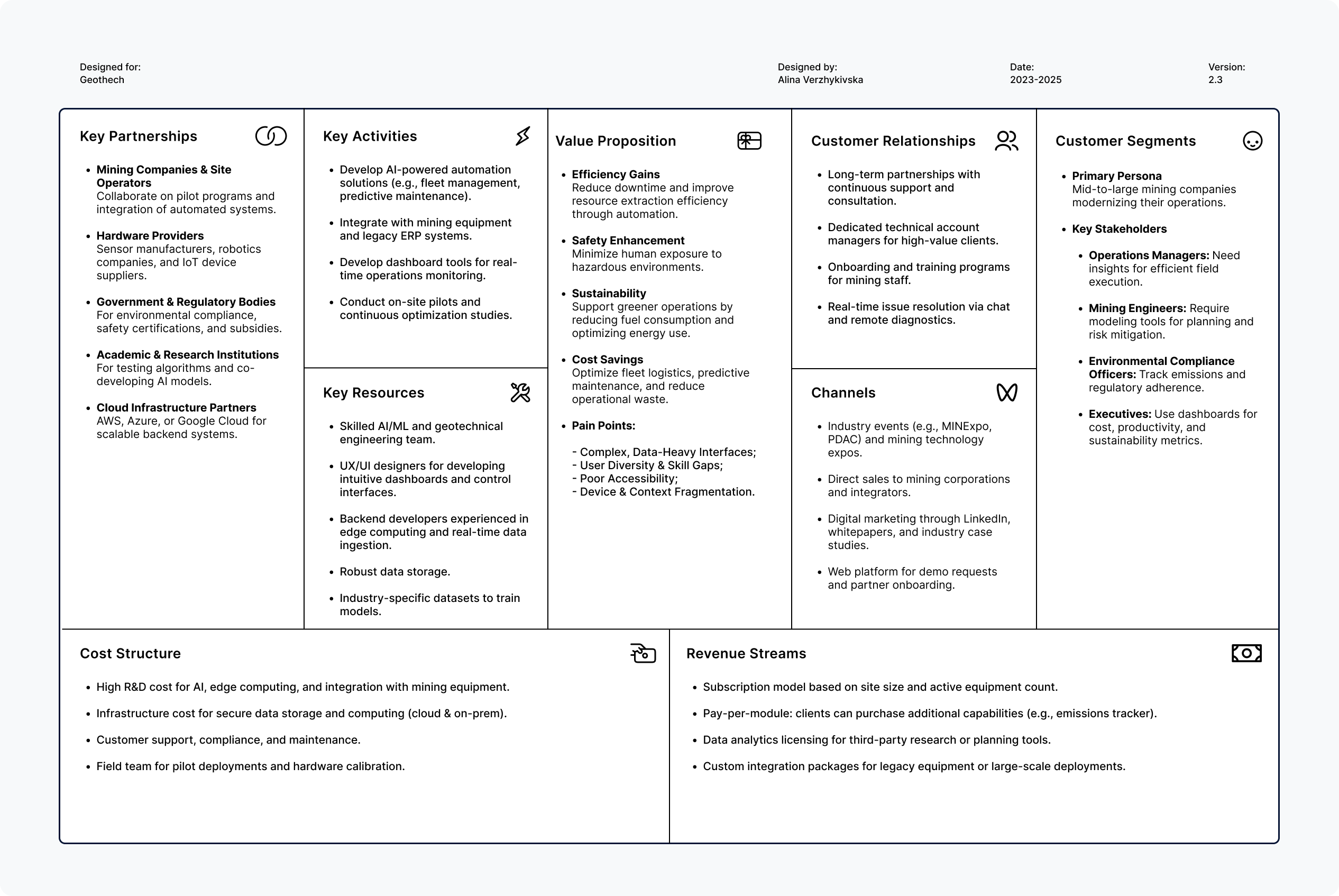

Business model canvas

06

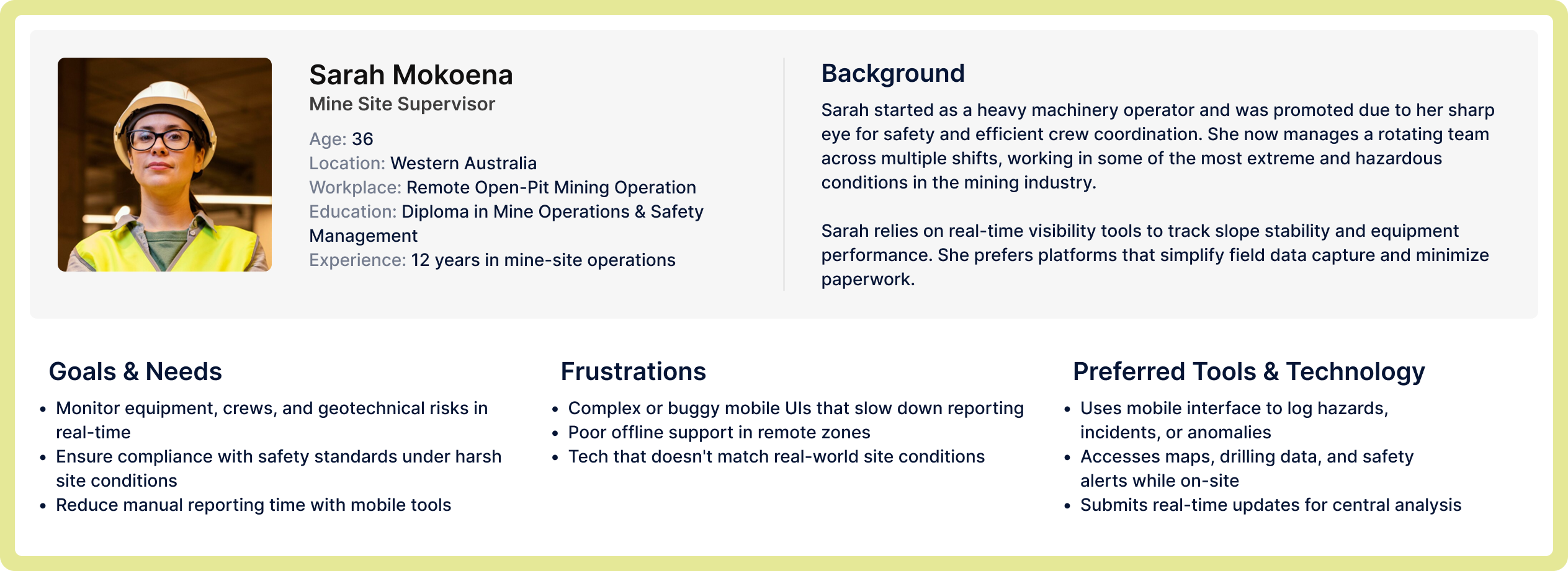

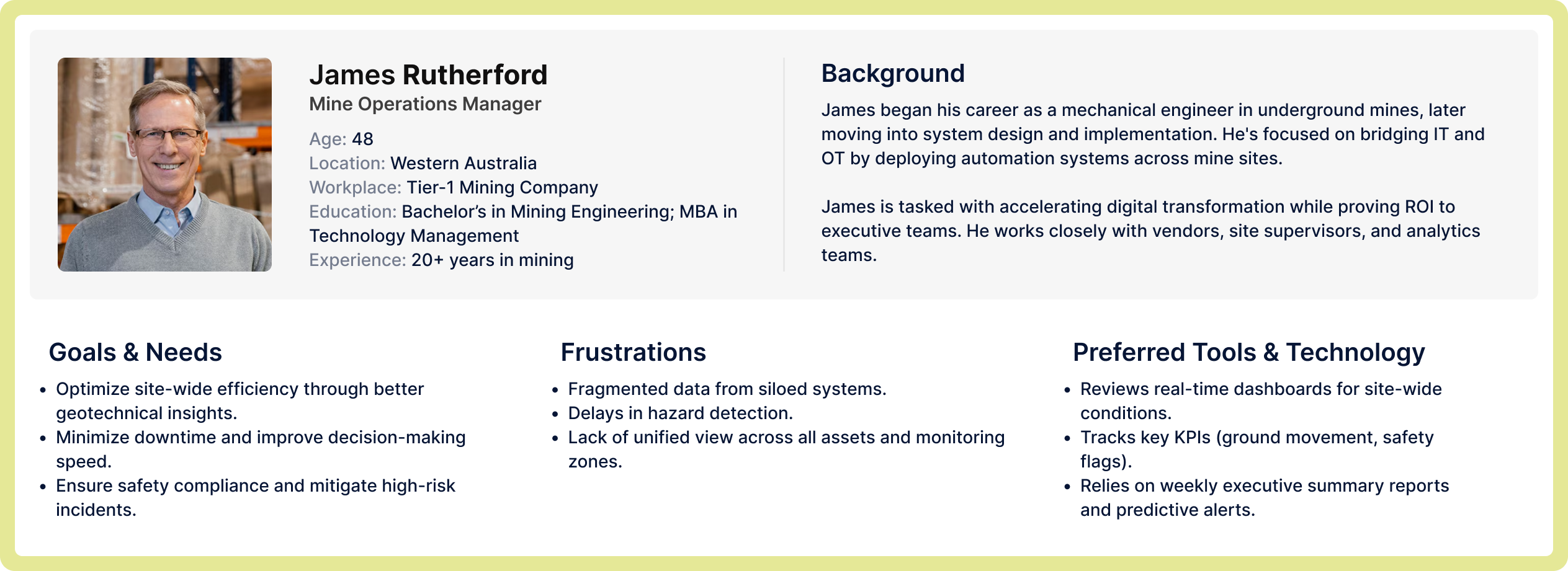

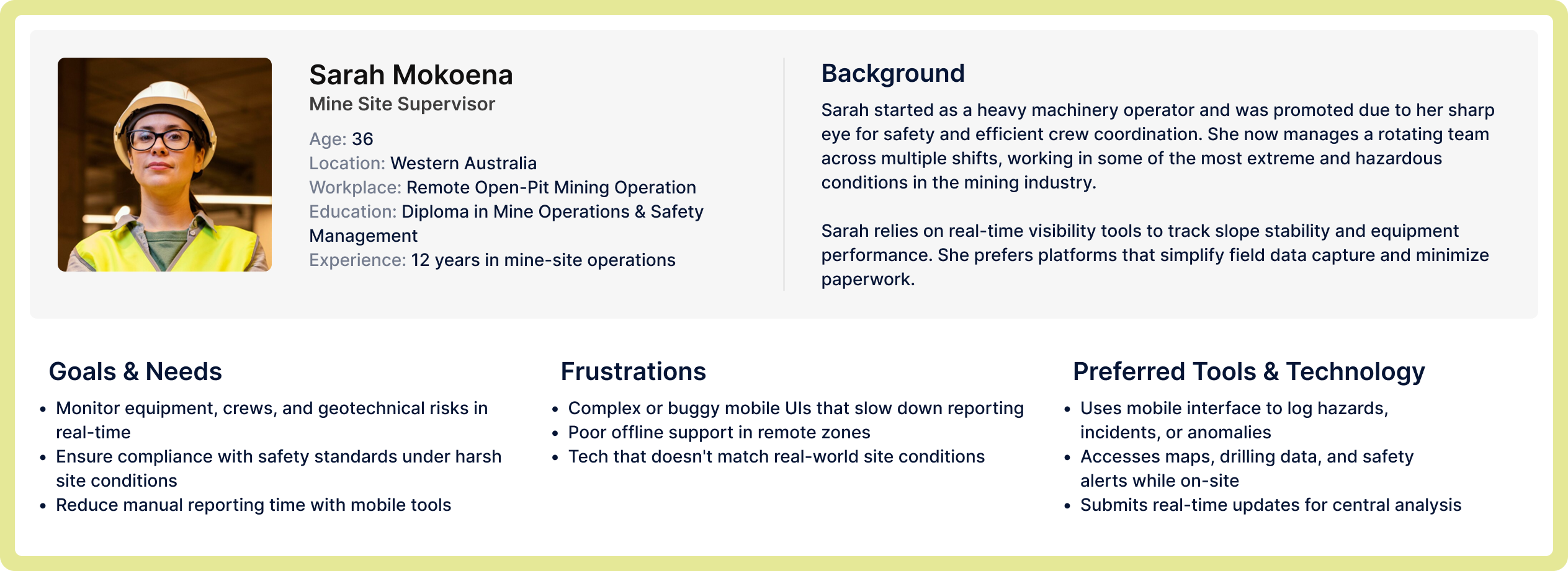

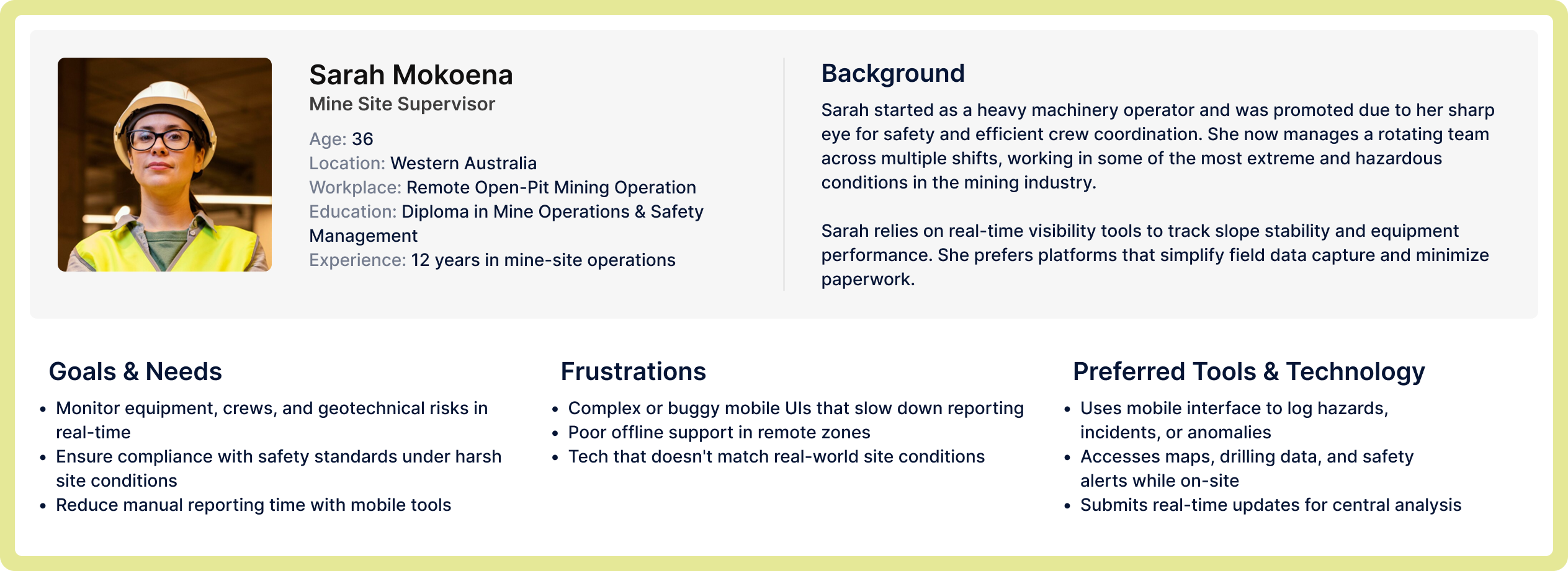

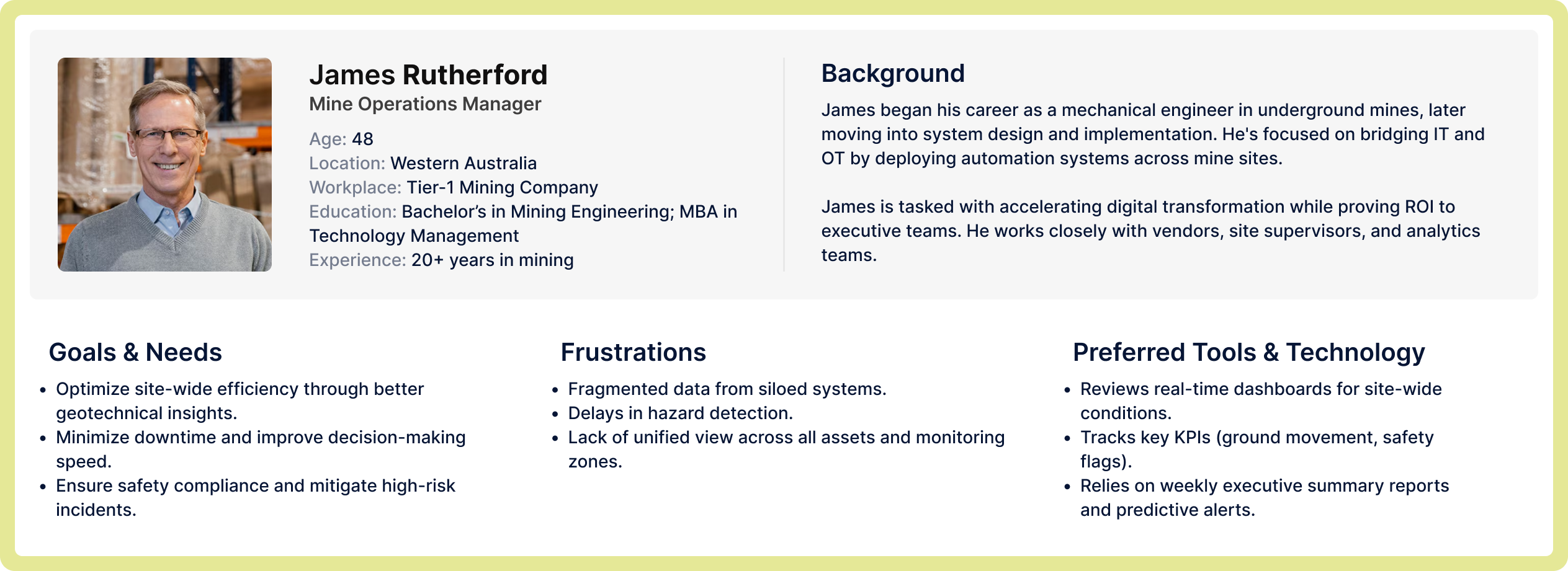

Customer persona definition

07

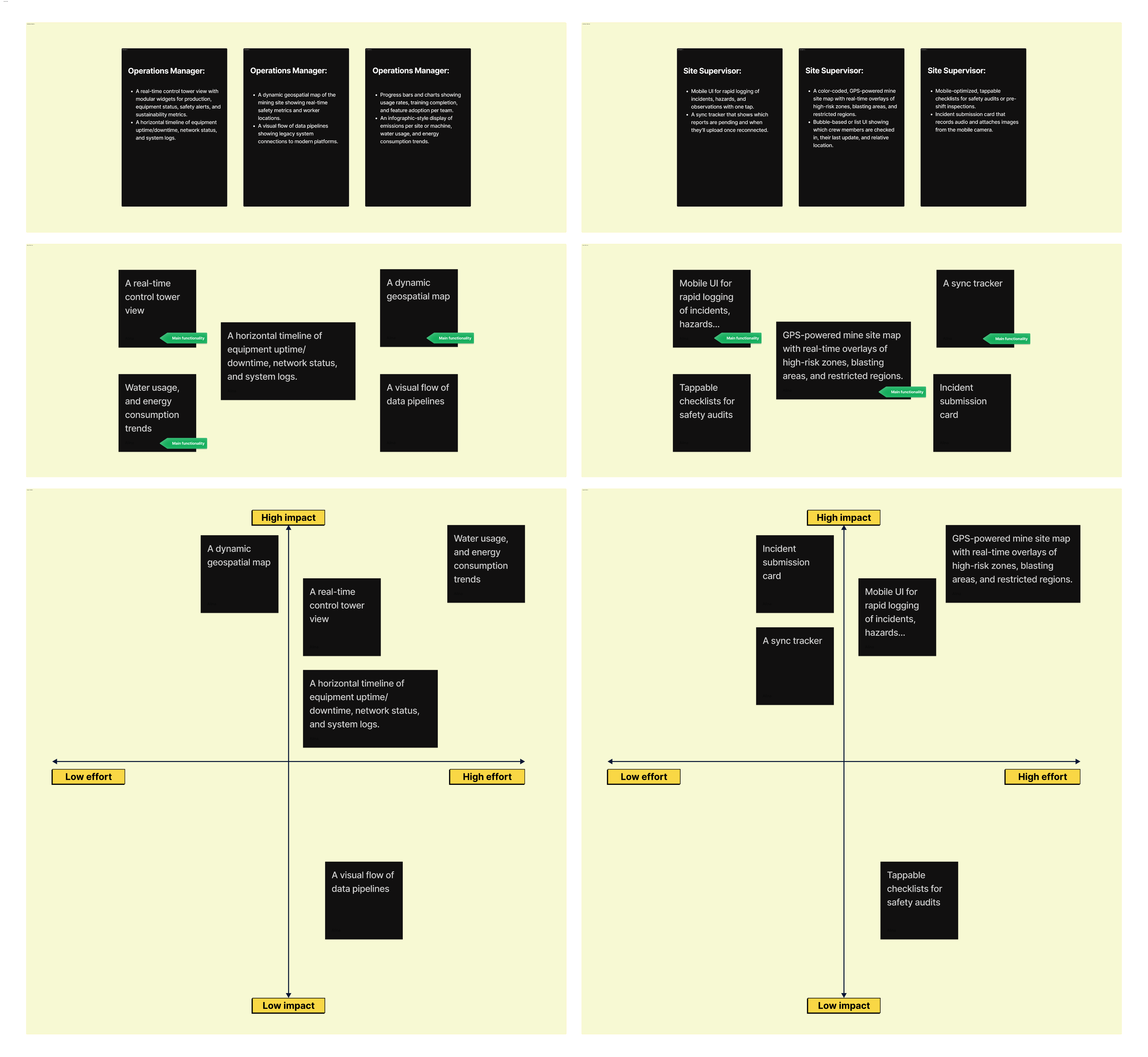

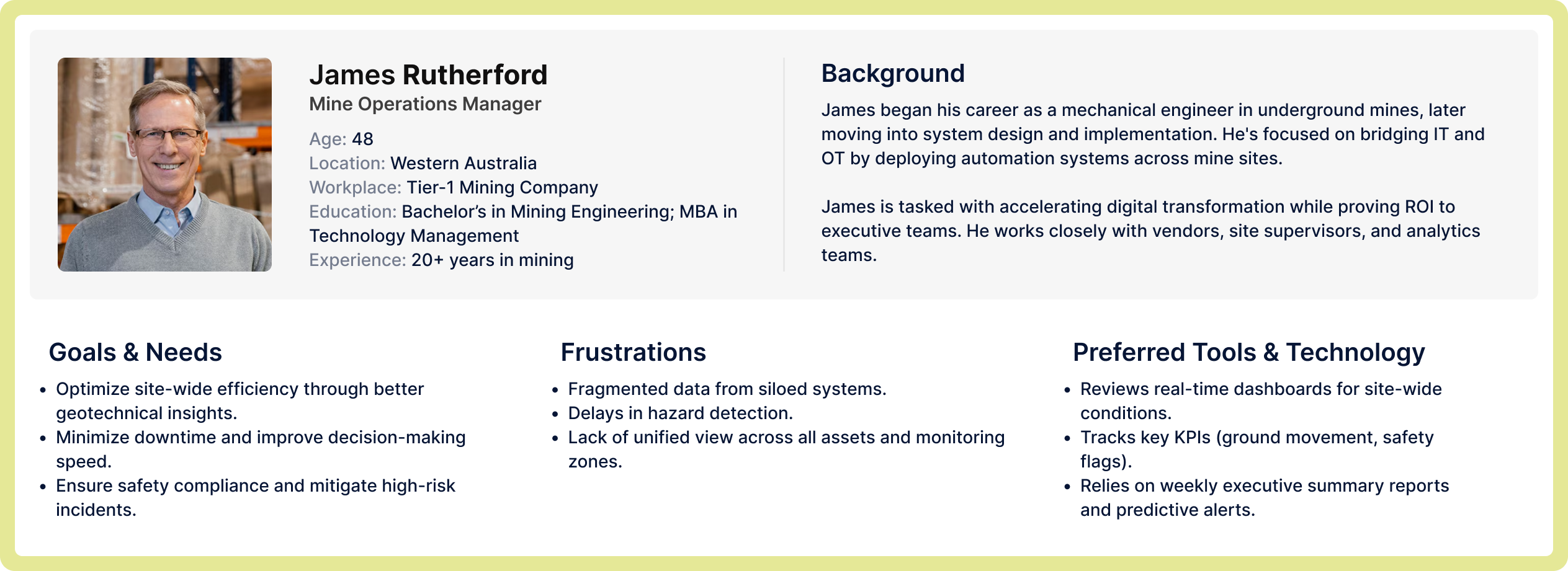

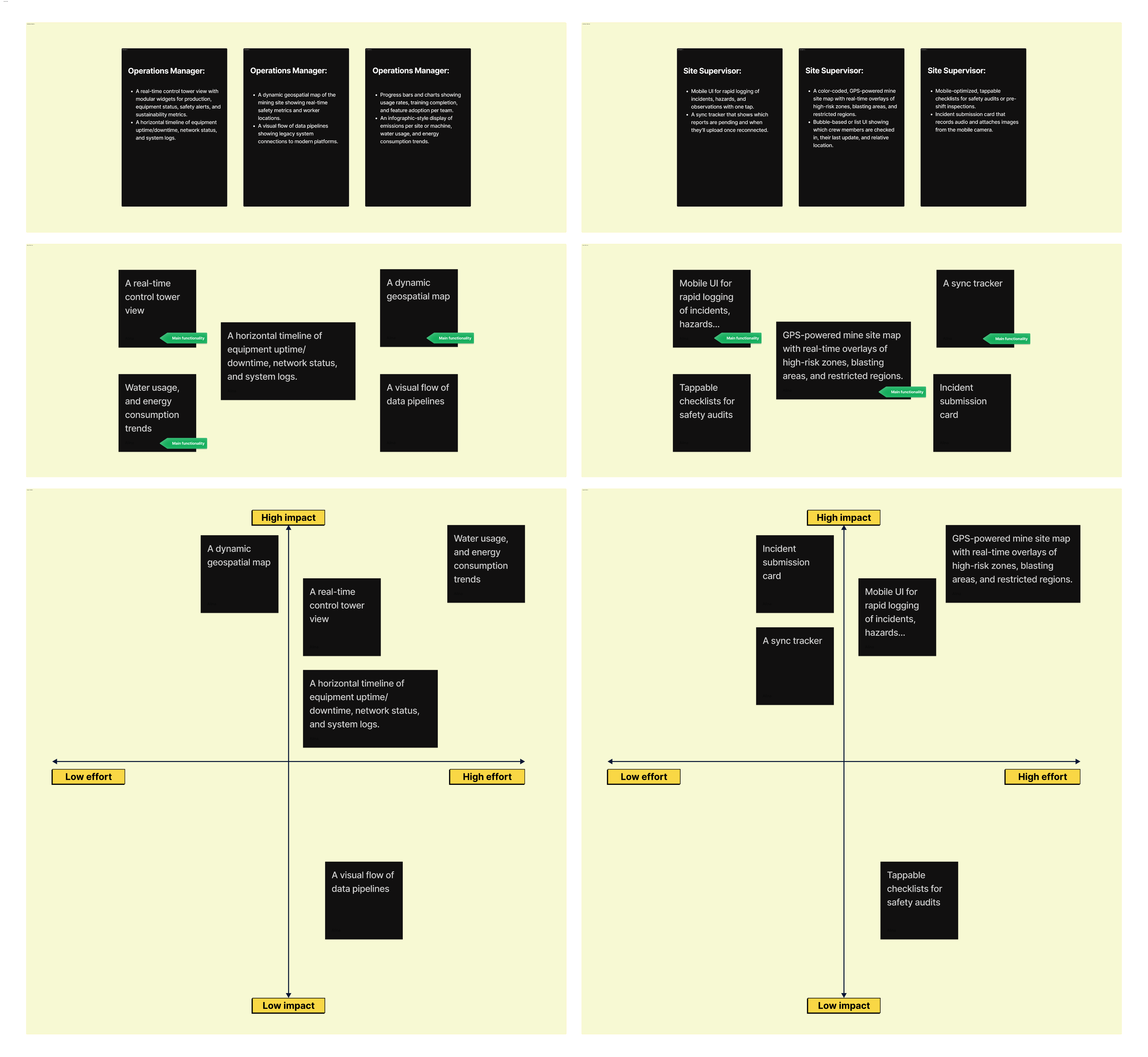

Ideation process

08

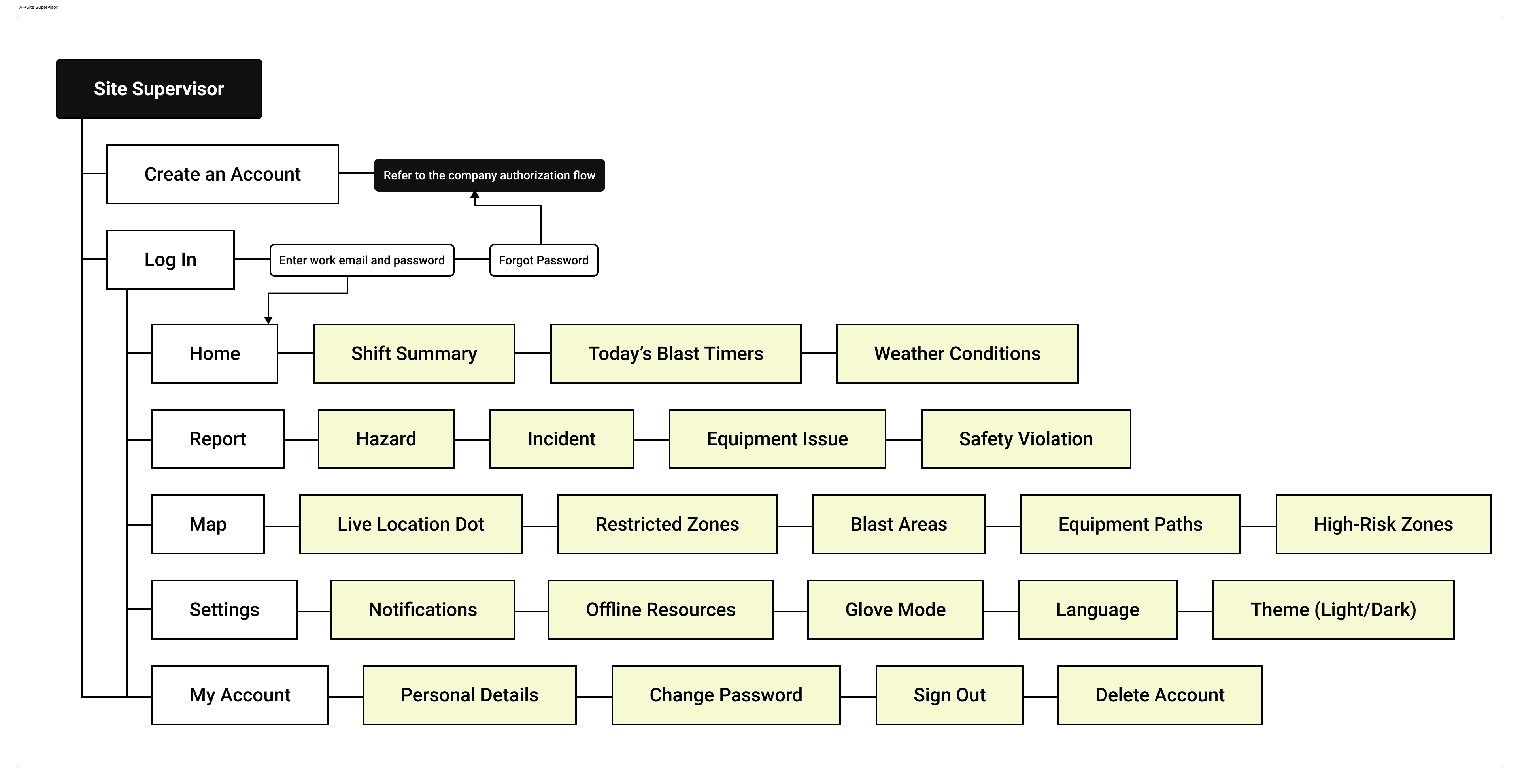

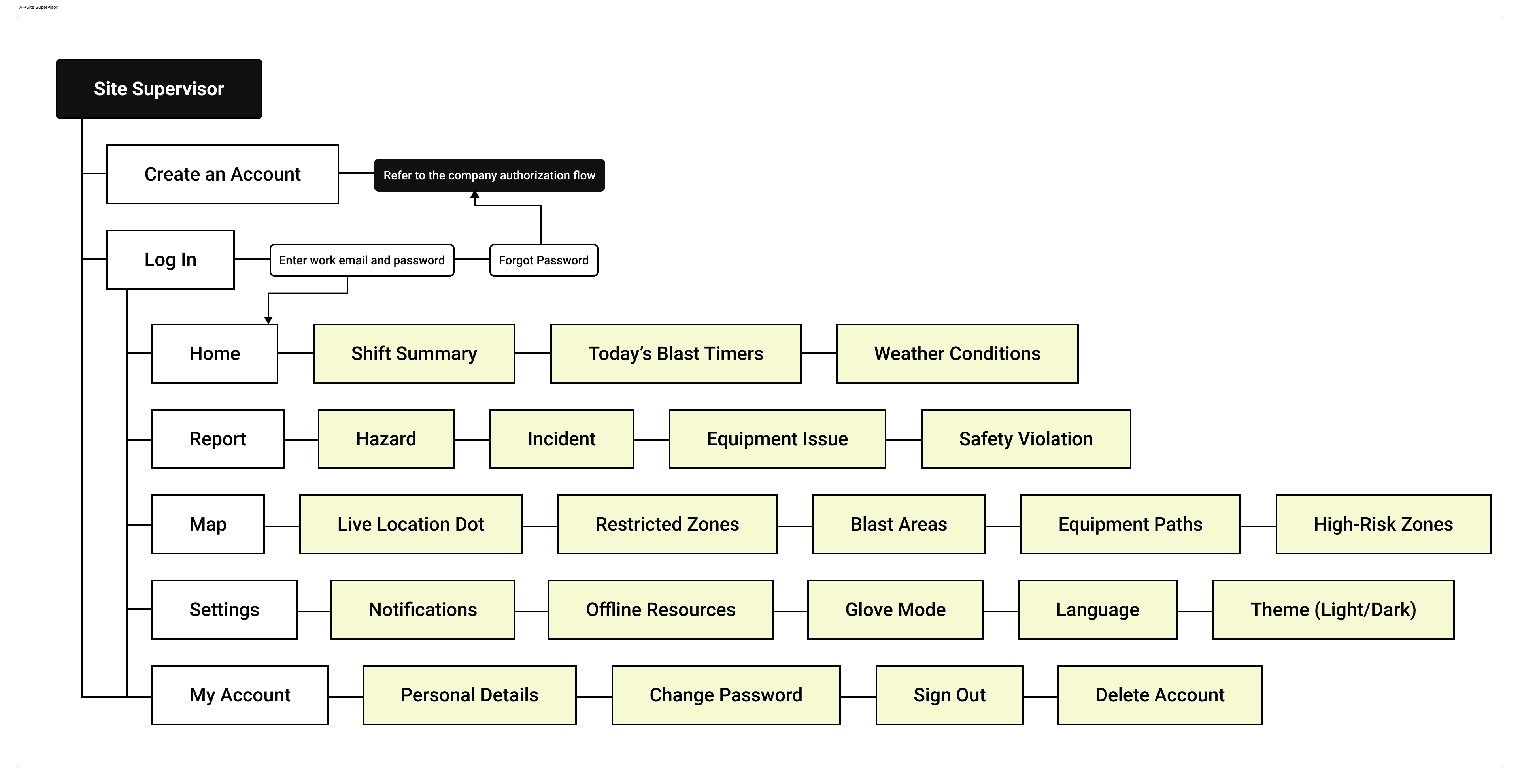

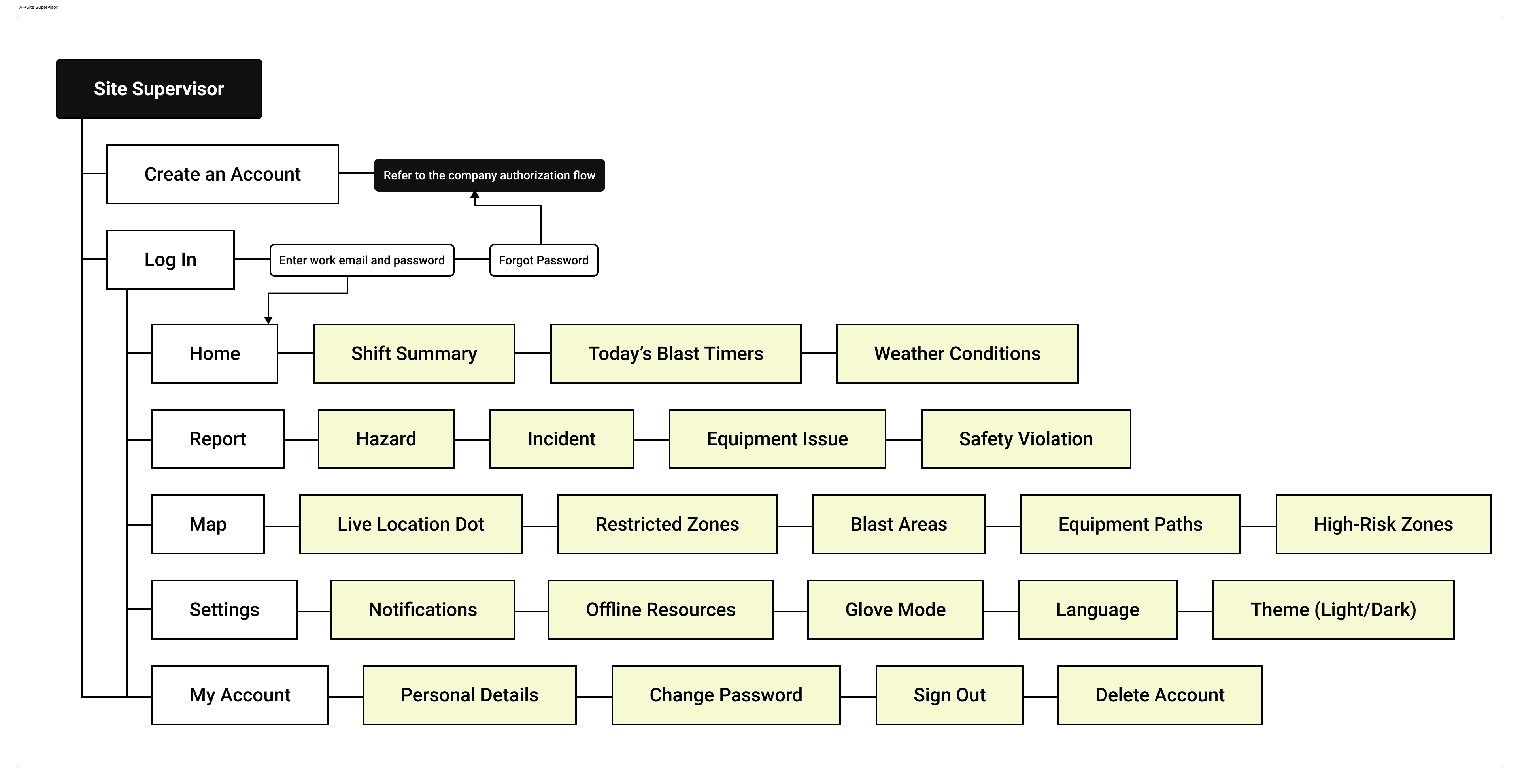

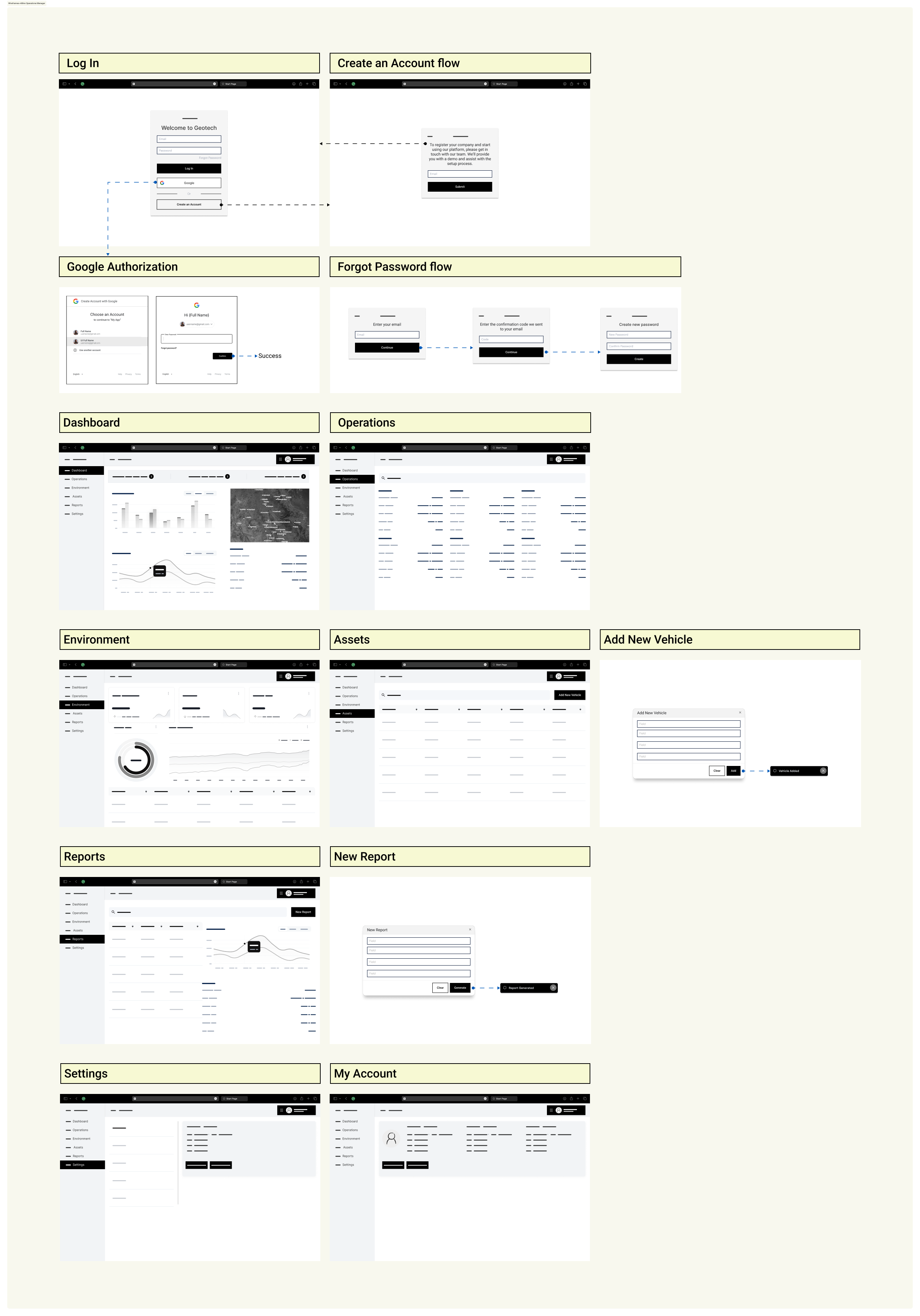

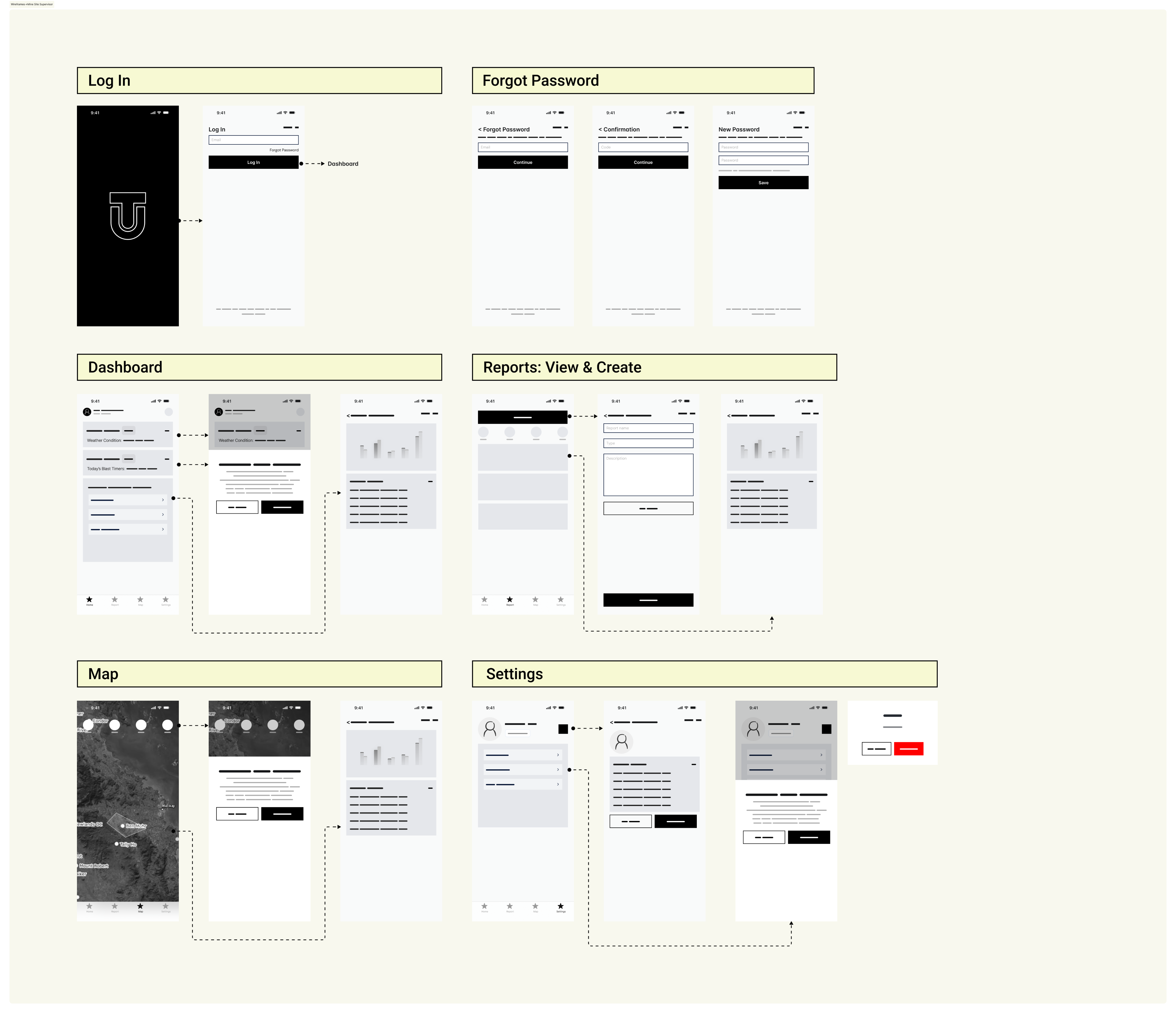

Information Architecture

09

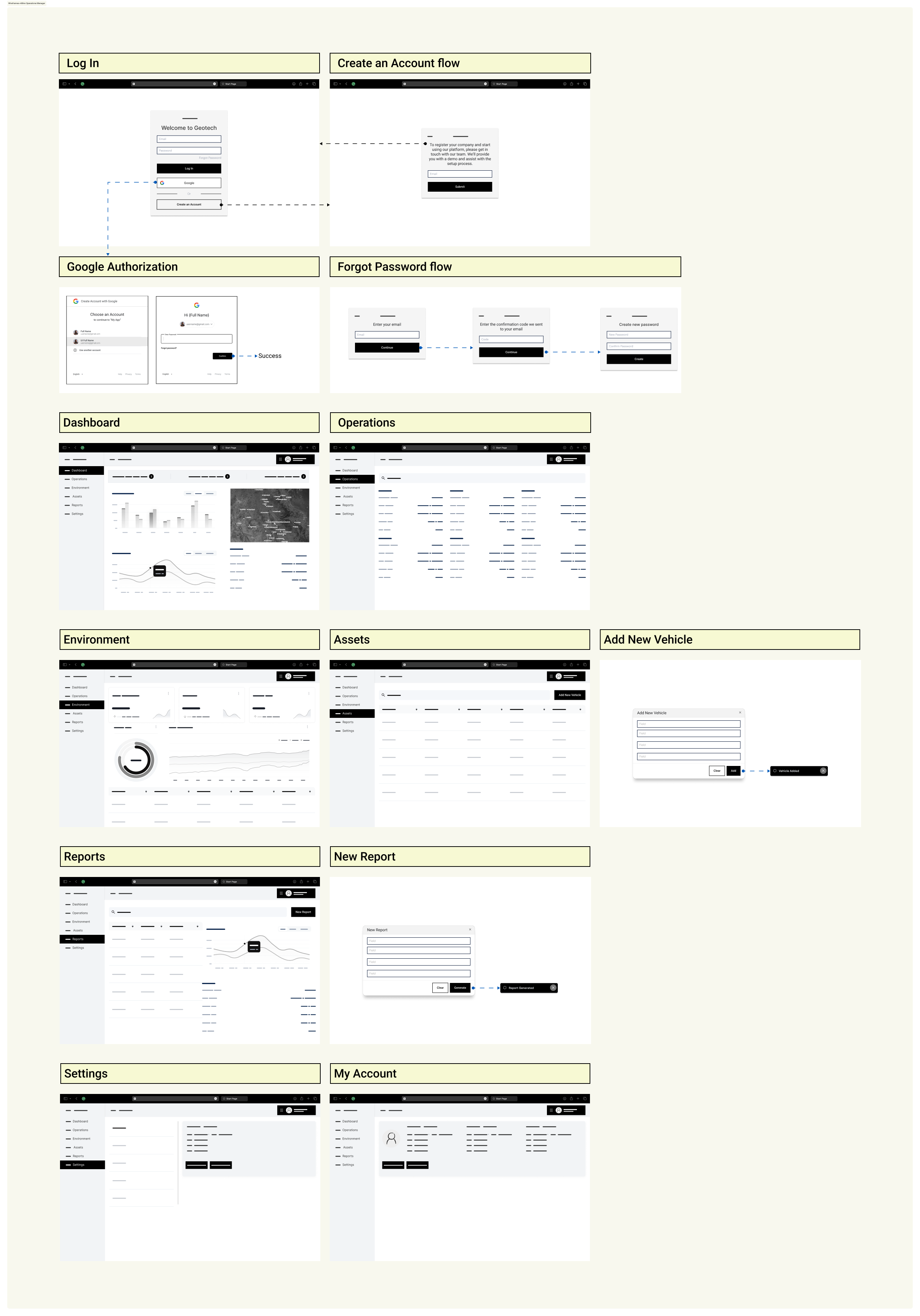

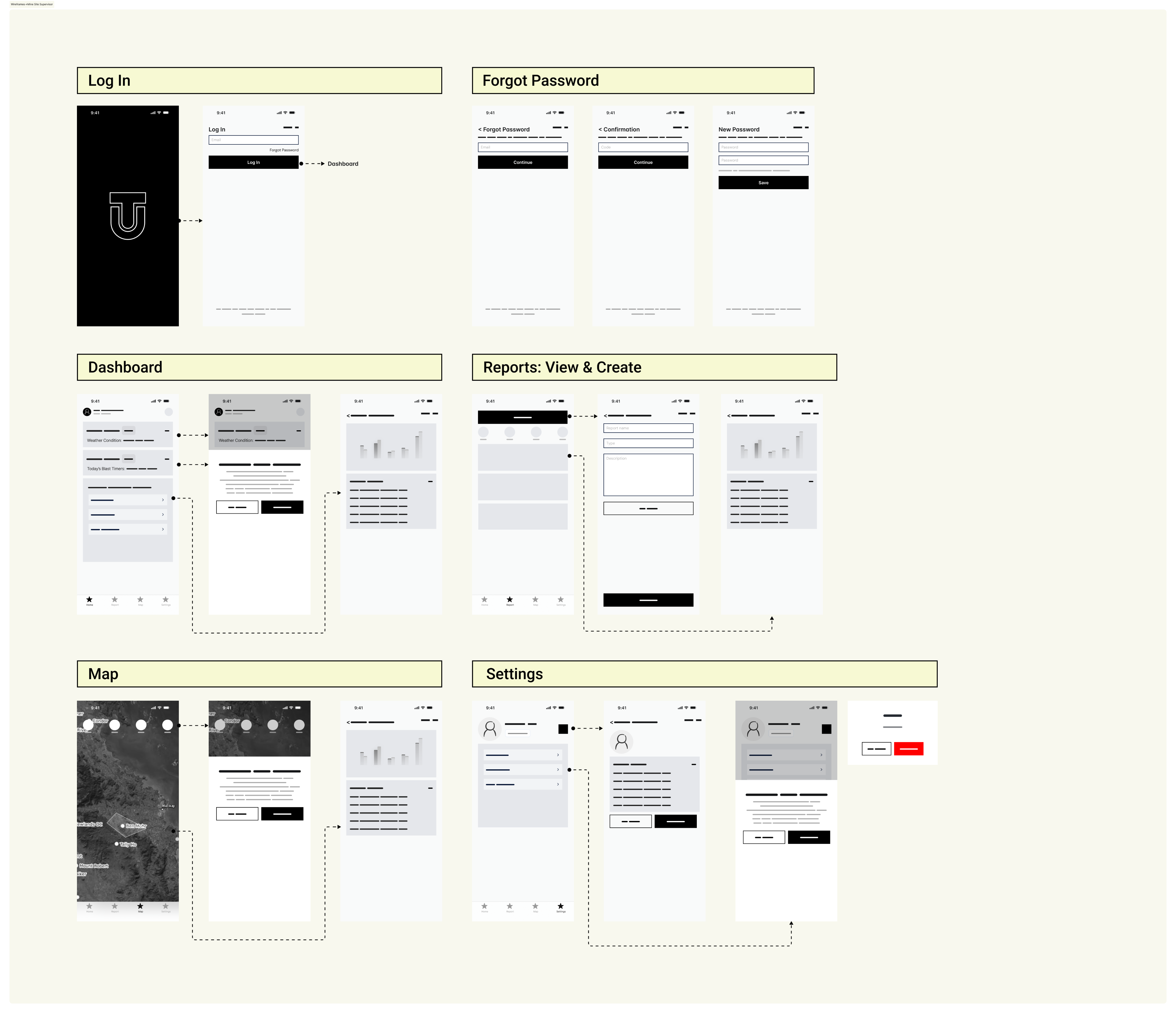

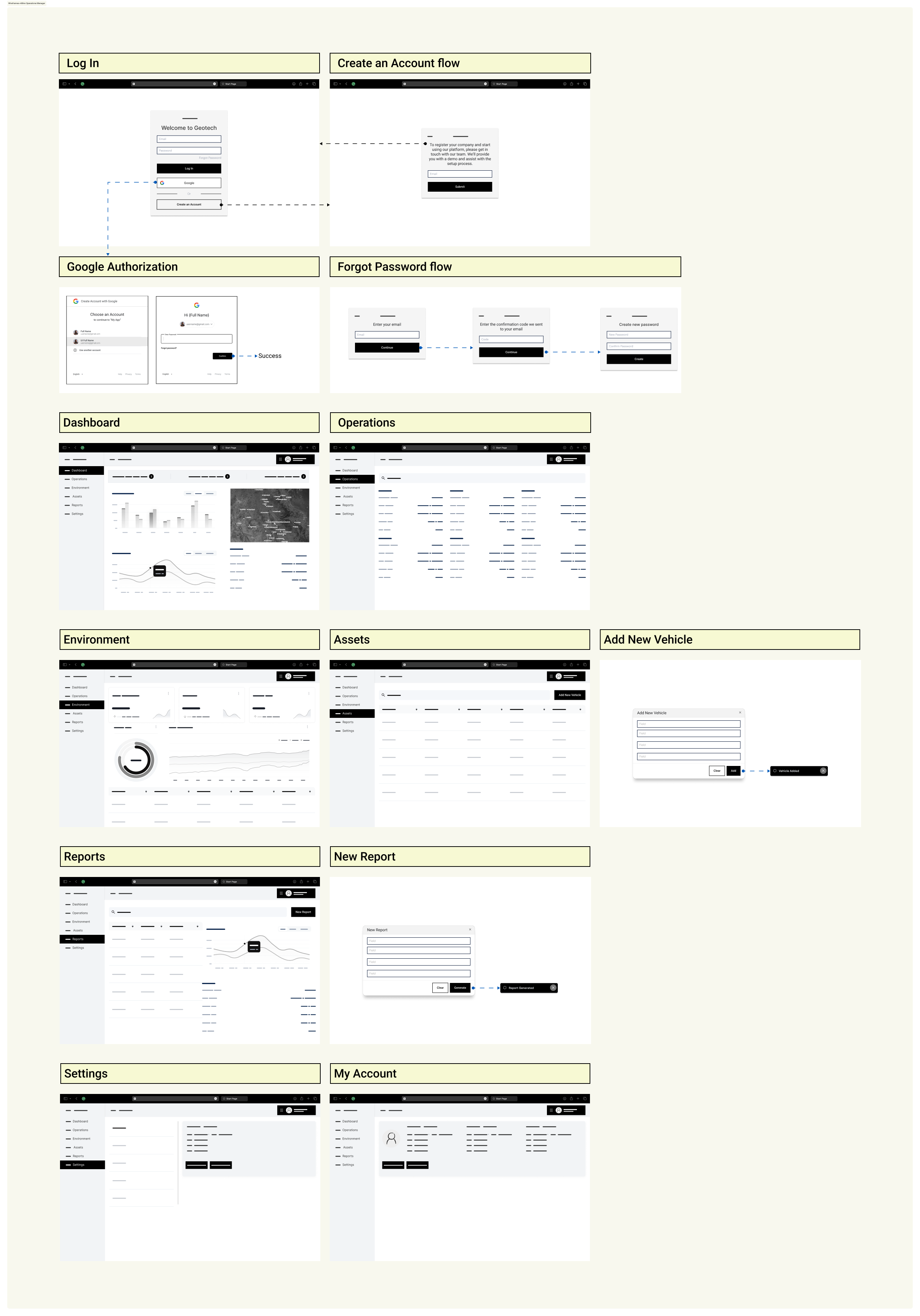

Prototyping

Mine Operations Manager

Geospatial insight. Depth-level tracking.

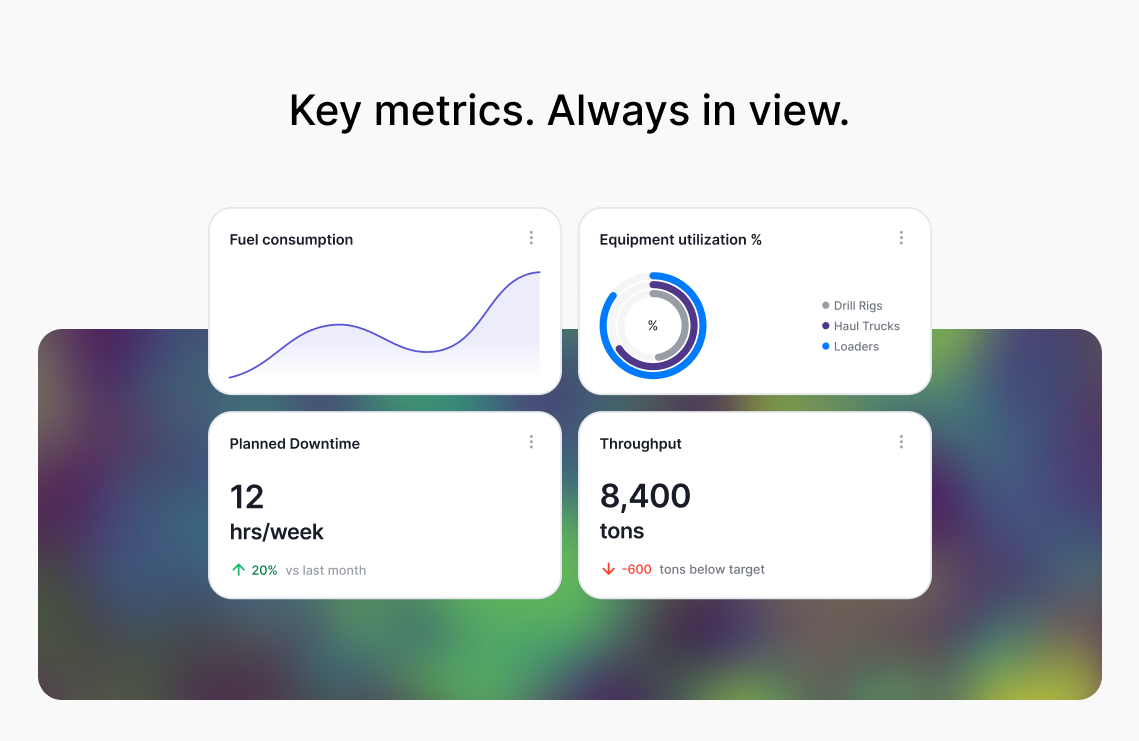

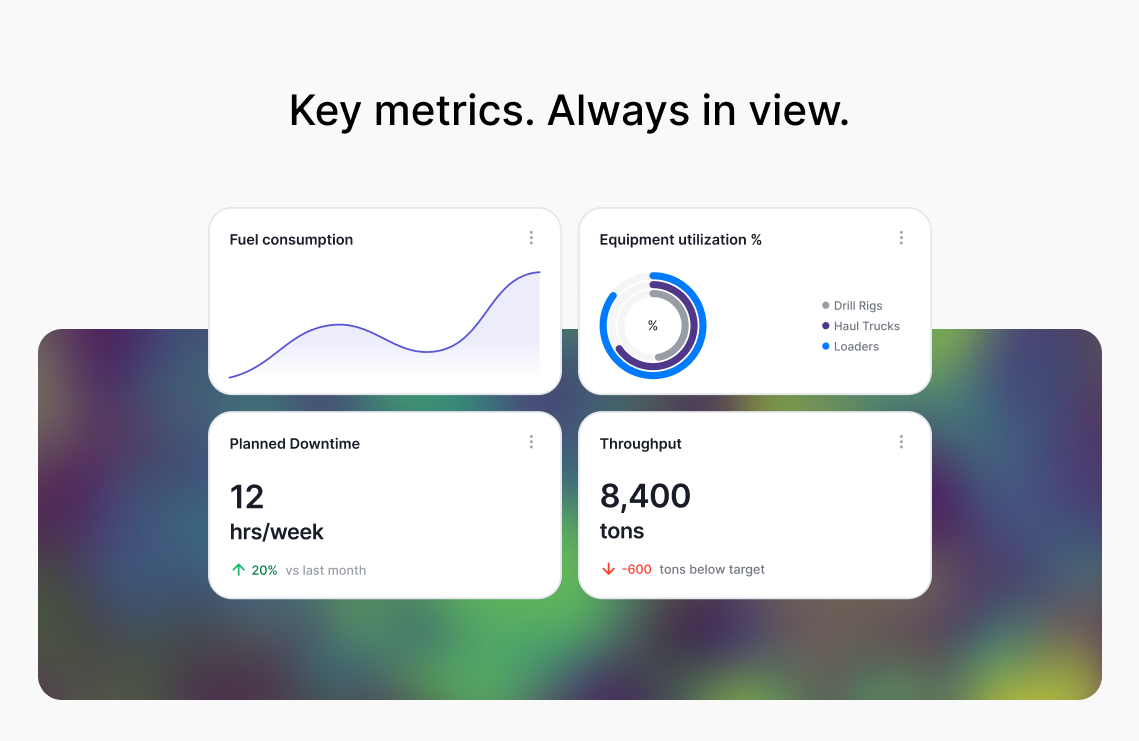

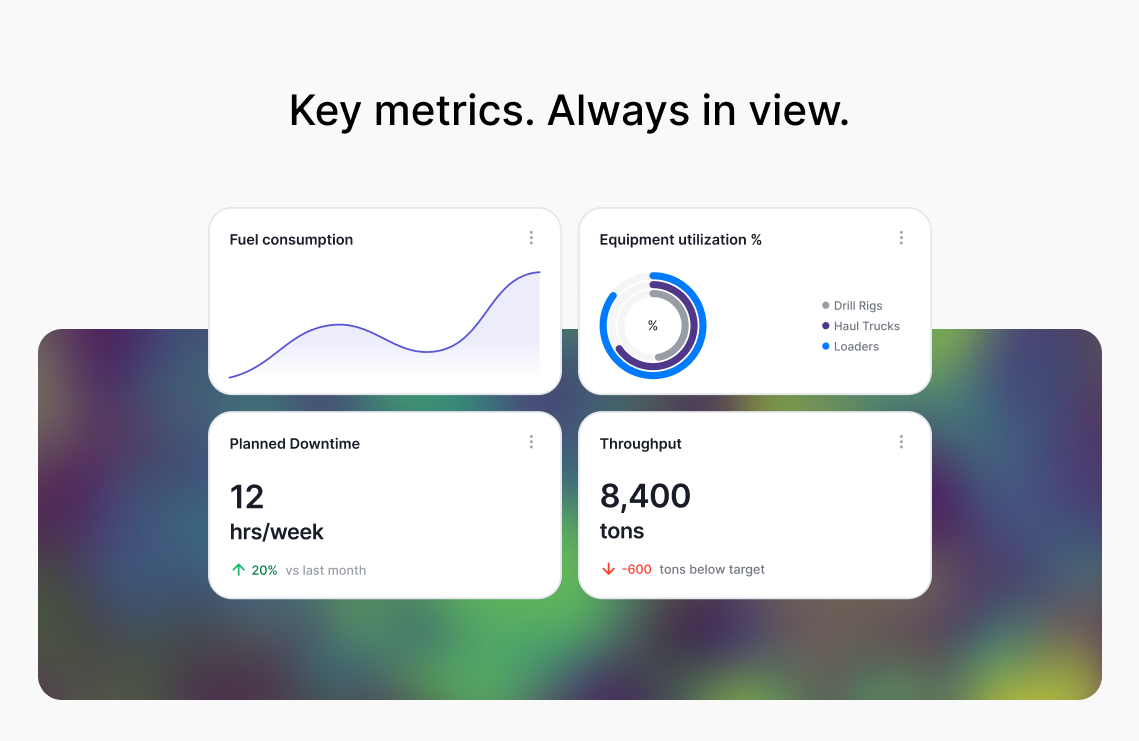

Key metrics. Always in view.

All Projects

@ Alina Verzhykivska 2025 | 0.26 CO2 per load

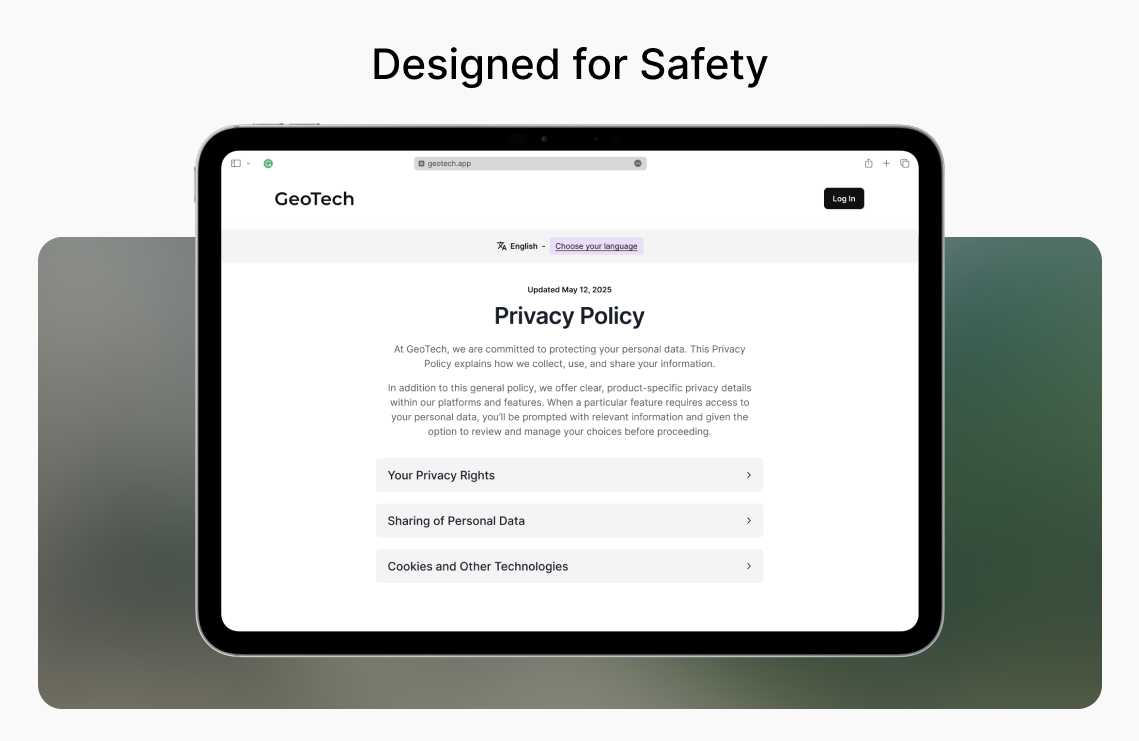

Privacy Policy

Industry 4.0

2024-2025

Automating depth measurement for mining and engineering

This was a challenging project due to its technical specifications. My main goals were to conduct stakeholder interviews, complete the project brief, define core functionalities in collaboration with the development team, and successfully launch the web application.

01

About the Platform

The project focuses on building an automated depth measurement platform for the mining, minerals, and civil engineering industries.

The goal is to design a product that combines advanced spatial analytics with a strategic design approach rooted in industry needs and design thinking principles.

02

Primary Market Research

Mining Automation Market valued at USD 5.33 billion in 2023, projected to reach USD 11.21 billion by 2030, growing at a CAGR of 11.19%.

03

Primary Market Research

Market Segmentation Analysis

The global mining automation market is segmented into 5 key categories: automation type, equipment type, mining technique, application, and end-use. This segmentation helps identify specific market trends, assess growth potential in sub-segments.

Automation Type

Automation equipment such as autonomous vehicles and robotic machinery are transforming mine sites by enabling 24/7 operation, reducing downtime, and minimizing the risks associated with manual labor in hazardous environments.

Equipment Type

The mining automation market encompasses a wide range of automated machinery, including:1. Automated Excavators and Loaders;2. Robotic Trucks and Loaders;3. Automated Drilling Systems;4. Autonomous Haulage Systems;5. Automated Mine Planning and Management Systems.

Mining Technique

Based on mining techniques, the market is divided into surface mining and underground mining. The underground mining segment is currently leading the market. Automation technologies are particularly valuable in underground environments due to the inherent challenges and risks associated with confined spaces, unstable geological conditions, and limited ventilation. Remote-operated machinery and intelligent drilling systems are well-suited to overcome these hurdles while ensuring operational safety and efficiency.

By Application

Mining automation is applied across three major operational phases:1. Mine Development;2. Mine Maintenance;3. Mining Operations.

By End-Use

The end-use segmentation includes:1. Mineral Mines;2. Coal Mines;3. Metal Mines.

04

Problem Definition Statement

''Mining companies are not well-known as technological disruptors. But there is a mandate now to invest more in technology to come up with solutions to the challenges of today — from ESG to productivity to ways of lowering costs.''

Manuel Fernandes, KPMG in Brazil

05

Business model canvas

06

Customer persona definition

07

Ideation process

08

Information Architecture

09

Prototyping

Mine Operations Manager

Geospatial insight. Depth-level tracking.

Key metrics. Always in view.

All Projects

@ Alina Verzhykivska 2025 | 0.26 CO2 per load

Privacy Policy

Industry 4.0

2024-2025

Automating depth measurement for mining and engineering

This was a challenging project due to its technical specifications. My main goals were to conduct stakeholder interviews, complete the project brief, define core functionalities in collaboration with the development team, and successfully launch the web application.

01

About the Platform

The project focuses on building an automated depth measurement platform for the mining, minerals, and civil engineering industries.

The goal is to design a product that combines advanced spatial analytics with a strategic design approach rooted in industry needs and design thinking principles.

02

Primary Market Research

Mining Automation Market valued at USD 5.33 billion in 2023, projected to reach USD 11.21 billion by 2030, growing at a CAGR of 11.19%.

03

Primary Market Research

Market Segmentation Analysis

The global mining automation market is segmented into 5 key categories: automation type, equipment type, mining technique, application, and end-use. This segmentation helps identify specific market trends, assess growth potential in sub-segments.

Automation Type

Automation equipment such as autonomous vehicles and robotic machinery are transforming mine sites by enabling 24/7 operation, reducing downtime, and minimizing the risks associated with manual labor in hazardous environments.

Equipment Type

The mining automation market encompasses a wide range of automated machinery, including:1. Automated Excavators and Loaders;2. Robotic Trucks and Loaders;3. Automated Drilling Systems;4. Autonomous Haulage Systems;5. Automated Mine Planning and Management Systems.

Mining Technique

Based on mining techniques, the market is divided into surface mining and underground mining. The underground mining segment is currently leading the market. Automation technologies are particularly valuable in underground environments due to the inherent challenges and risks associated with confined spaces, unstable geological conditions, and limited ventilation. Remote-operated machinery and intelligent drilling systems are well-suited to overcome these hurdles while ensuring operational safety and efficiency.

By Application

Mining automation is applied across three major operational phases:1. Mine Development;2. Mine Maintenance;3. Mining Operations.

By End-Use

The end-use segmentation includes:1. Mineral Mines;2. Coal Mines;3. Metal Mines.

04

Problem Definition Statement

''Mining companies are not well-known as technological disruptors. But there is a mandate now to invest more in technology to come up with solutions to the challenges of today — from ESG to productivity to ways of lowering costs.''

Manuel Fernandes, KPMG in Brazil

05

Business model canvas

06

Customer persona definition

07

Ideation process

08

Information Architecture

09

Prototyping

Mine Operations Manager

Geospatial insight. Depth-level tracking.

Key metrics. Always in view.

All Projects

@ Alina Verzhykivska 2025 | 0.26 CO2 per load